I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

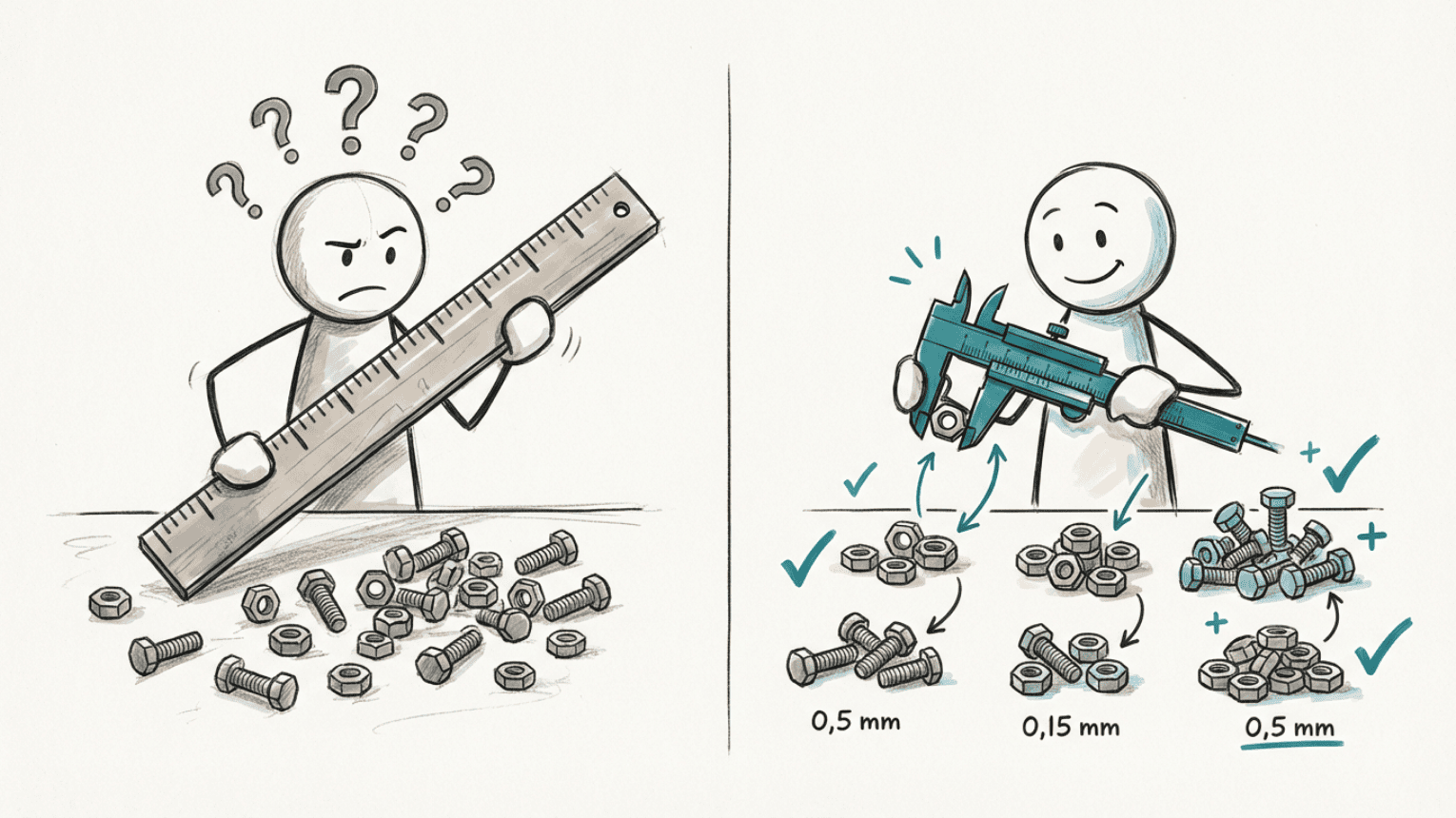

Before you ask 'why', ask 'how often'.

They took 600 samples per year chasing process problems. Then they discovered the issue was the measurement system.

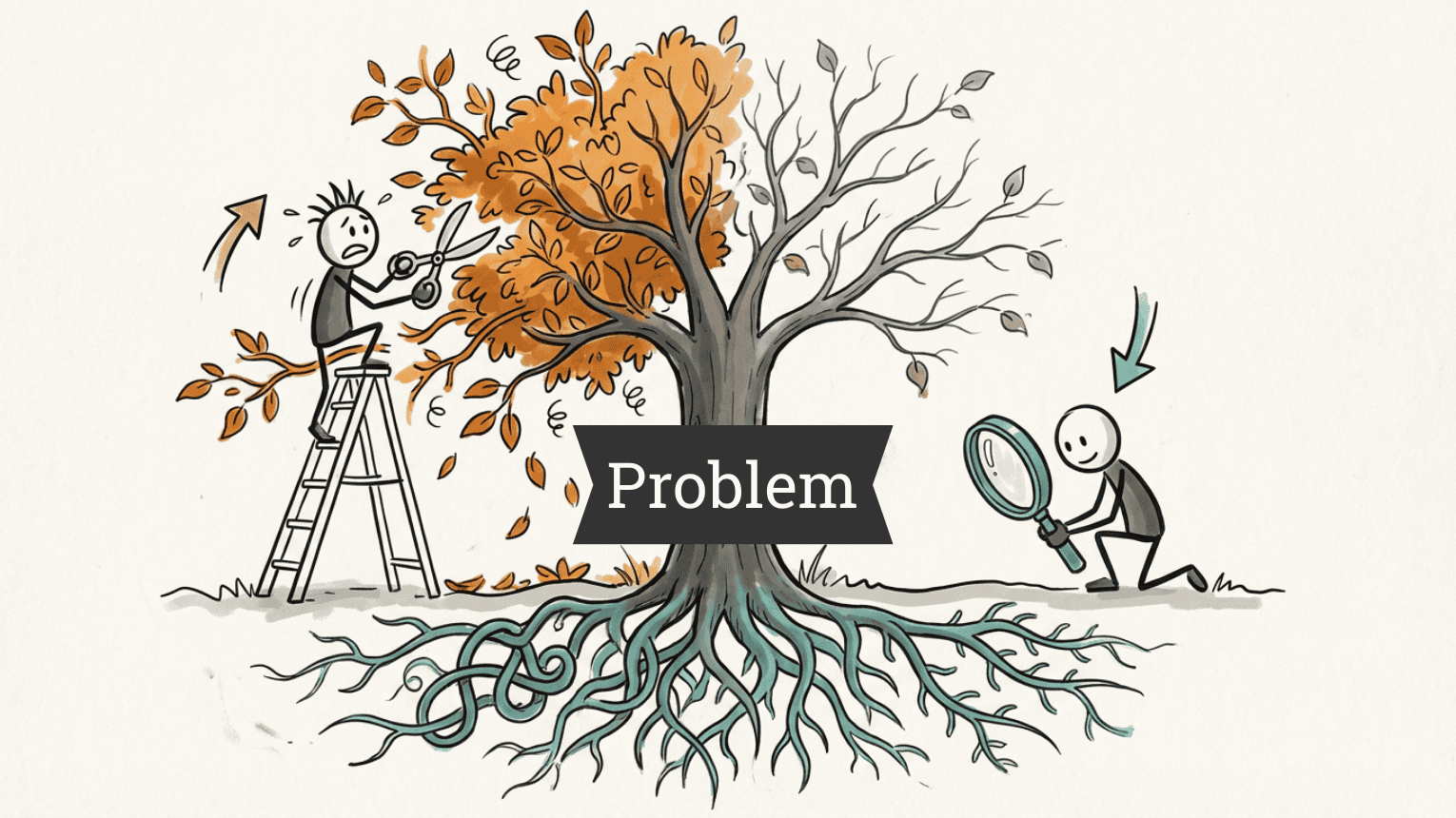

A client asked for root cause analysis training, but really wanted to get better at firefighting.

The Lead Lean conference focused on exploitation (optimization) and exploration (innovation).

How can Lean Six Sigma contribute to both?

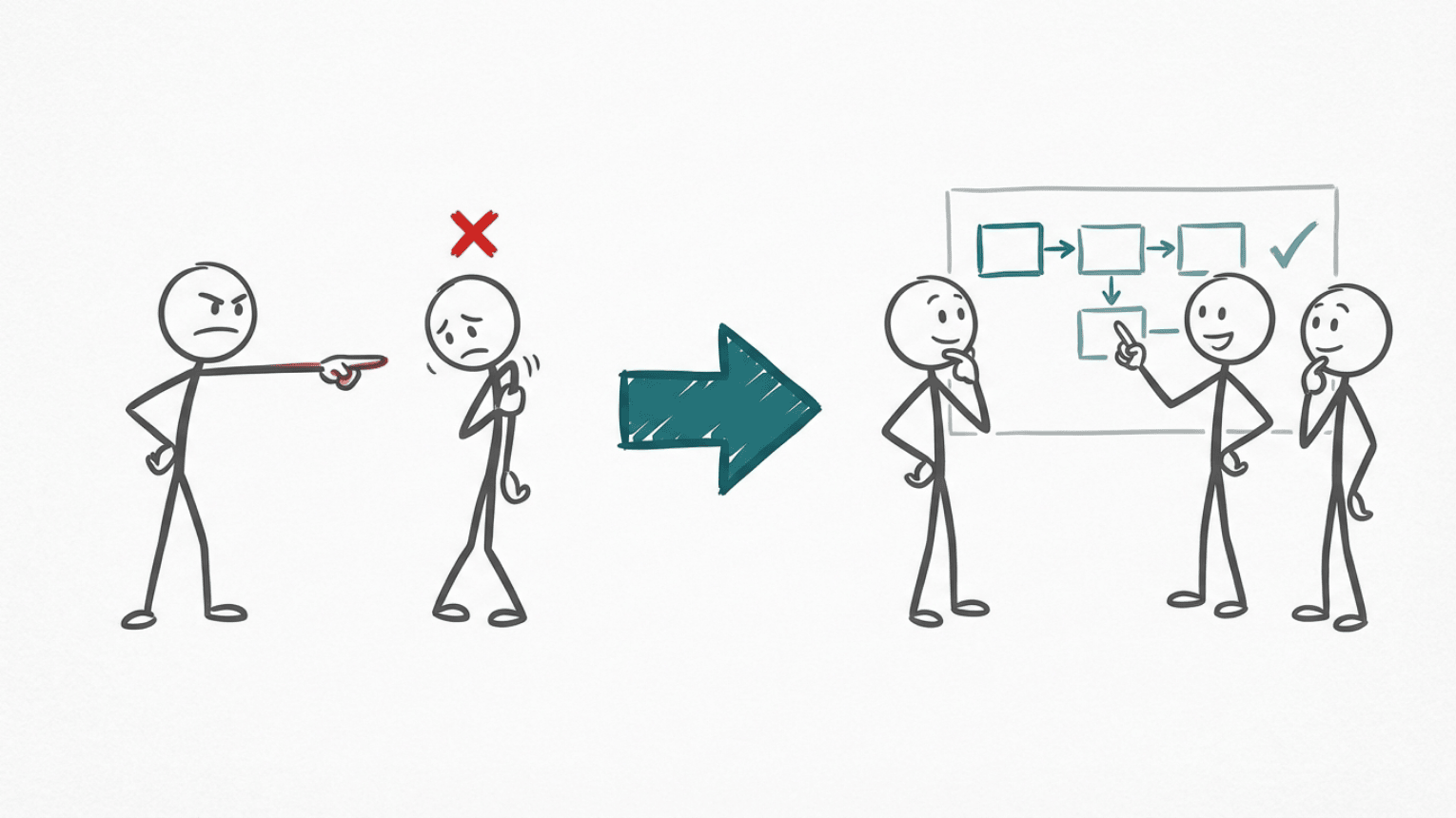

«A bad process will beat a good person every time» - W. Edwards Deming

I was on a job trip, where the return journey did not go according to plan.

The result was a missed air plane, and Hertz received a damaged car in return.

What really happened and what was the root cause?

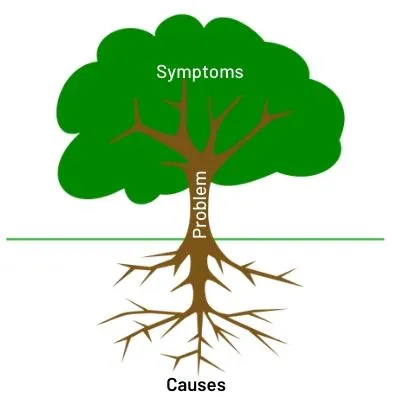

The purpose of a root cause analysis is to determine the true causes of a problem to implement targeted measures.

As the picture illustrates, a problem (the tree) can have many causes (roots). Over time, the symptoms (leaves of the tree) and the problem (tree) grow larger and become more and more visible.

I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

Very nice and professional service. Delivered a good job within deadlines.

Sissel's commitment and expertise is impressive. Her contribution to our monitoring program has been precise and targeted, as well as very educational.

We are very happy with the work carried out; with your background and expertise, the outcome was what we were looking for.

Sissel is a competent and committed employee. She has been an important contributor to ensure progress. At the same time, she is accurate and deliveres good quality work.

Lean Tech delivered monitoring program for air emission. The assignment was delivered with the correct content at the right time. Recommended.

Very engaged and focused throughout the course. Sticking to the agenda. Nice and pleasant.

Very good at keeping the right atmosphere, and at driving the participation from all the attendees.

Supply Chain & Automation Manager

"You are inspiring, positive and professionally skilled" "Made a difference, engaged and skilled"

"Inspiring, motivating and patient. Managed to adjust the subject to our level."

"Very knowledgeable. Good answers to all input."

"Excellent! Very clever and engaging"

"Great and fun with the Lego competition."

"Very good! Lots of knowledge and good at communicating."

"Good mix of theory and practice. Fun to try out what you've learned."

Very useful with practical implementation and approach, and that we could relate / transfer to our own workplace.

Inspiring, professionally competent, popularize a theoretical discipline.

Clear and well presented. Good at asking questions and listen (check understanding).

Academic highly skilled and clear performance. Fun and builds trust.

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up