I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

"Process mapping makes it so much easier to see improvements!" - Course participants, process mapping.

In a process mapping course, participants first got an introduction:

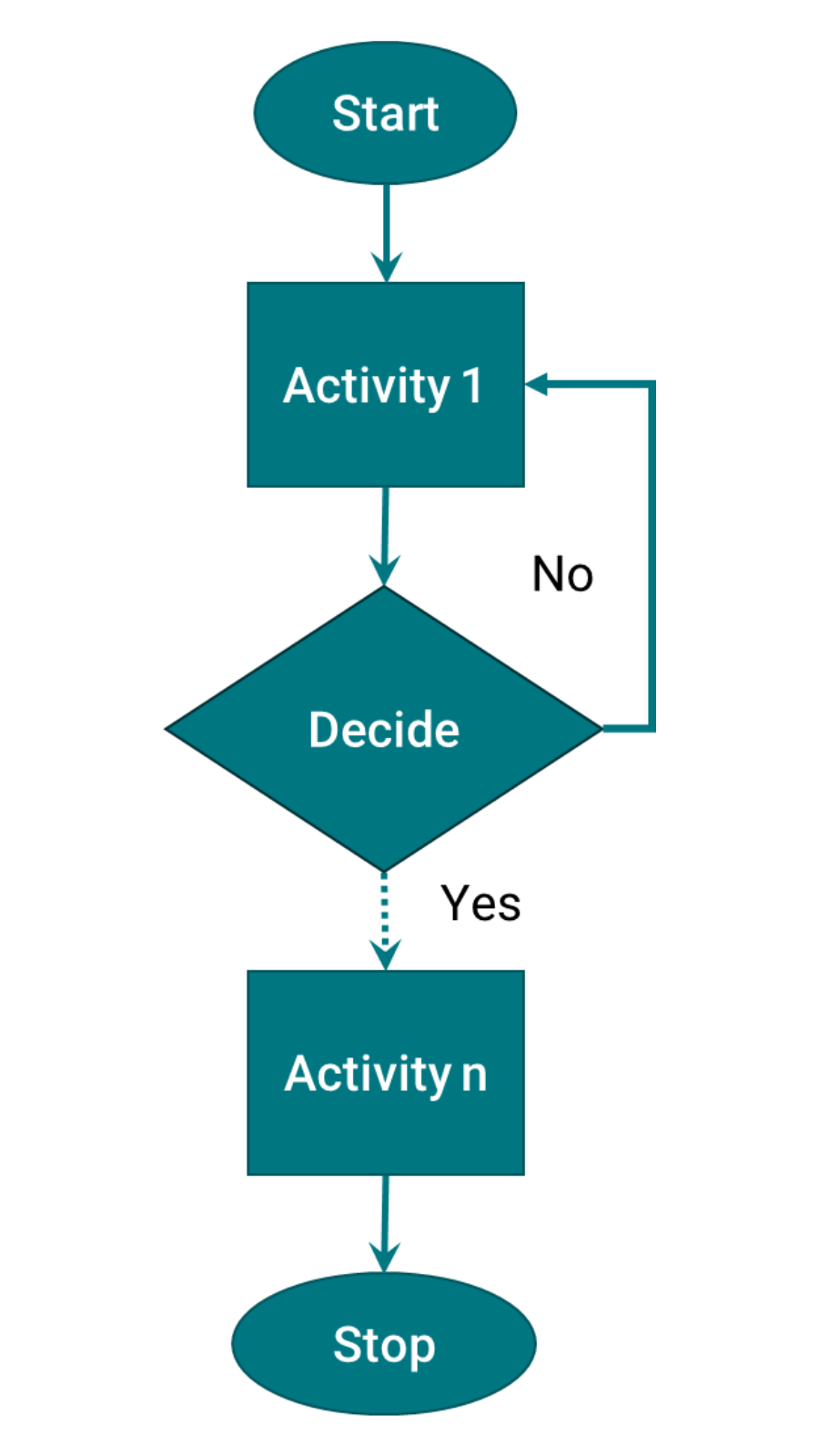

• Clear start and stop

• Verbs describing activities

• Right level of detail with focus on purpose

• Collaboration to build shared understanding

Then they practiced on their own processes. First, mapping the current state. Then looking for improvements.

Unanimous feedback from the group:

"Process mapping makes it so much easier to see improvements!"

They saw:

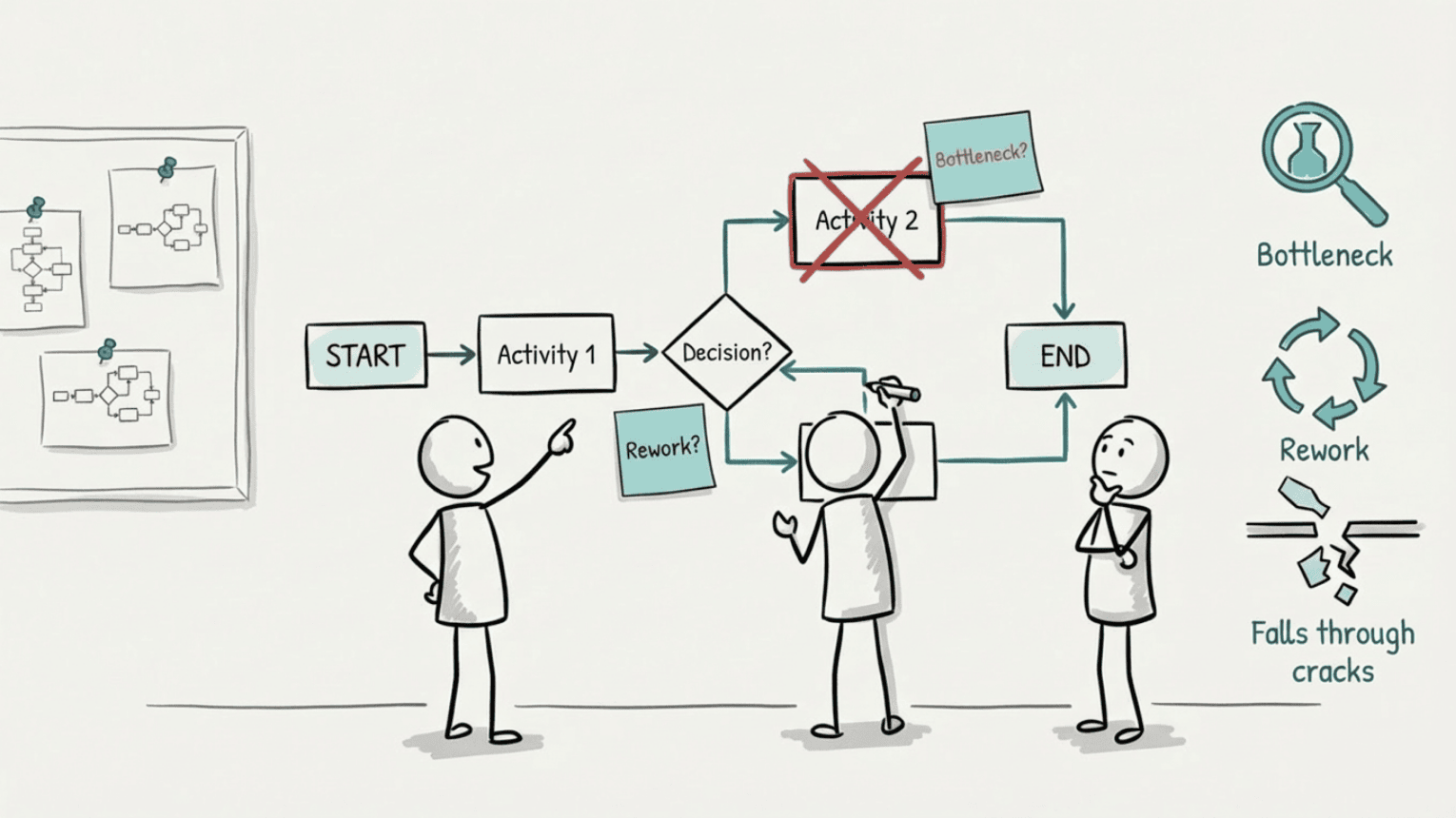

• Where bottlenecks occurred

• Where duplicate work happened

• Where things fell through the cracks

When you see the process, you see the opportunities.

Situation: Teams mapped their own processes and practiced the method on actual work tasks.

Insight: Visualizing the process made it immediately easier to see bottlenecks, duplicate work, and where things fell through the cracks.

Learning: You can't improve what you don't understand. And you can't understand the process until you've visualized it - as it actually is.

Application: Applies to all types of improvement - from municipal services to production and emissions control.

Process maps are visual tools that show how activities connect to achieve a result.

They're used for formal documentation, improvement, and designing new processes.

A bad process will give bad results, no matter how skilled the people involved are.

To improve a process, we must first understand it. Process mapping helps us see the process as it actually is - not as it should be or as we think it is.

First, we need to agree on how it actually works. Then we can improve.

To map the process correctly, we must see how it's actually performed - not how we think it works.

This means going to where the process happens, observing, asking questions, and involving those who do the work.

There are many types of process maps suited for different purposes:

Which process map suits your challenge best?

Maybe you recognize the dynamic:

• The team discusses how the process works, but no one's quite sure

• You discover problems but don't know where in the process they occur

• Improvement efforts focus on symptoms because you don't see the whole

• New employees learn the process differently because it's not visualized

• You spend time discussing who's responsible for what

The consequence? You improve the parts, but not the whole.

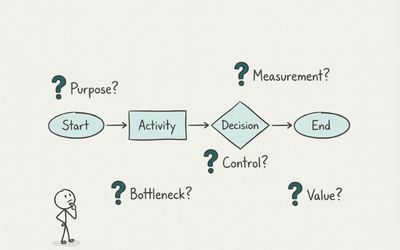

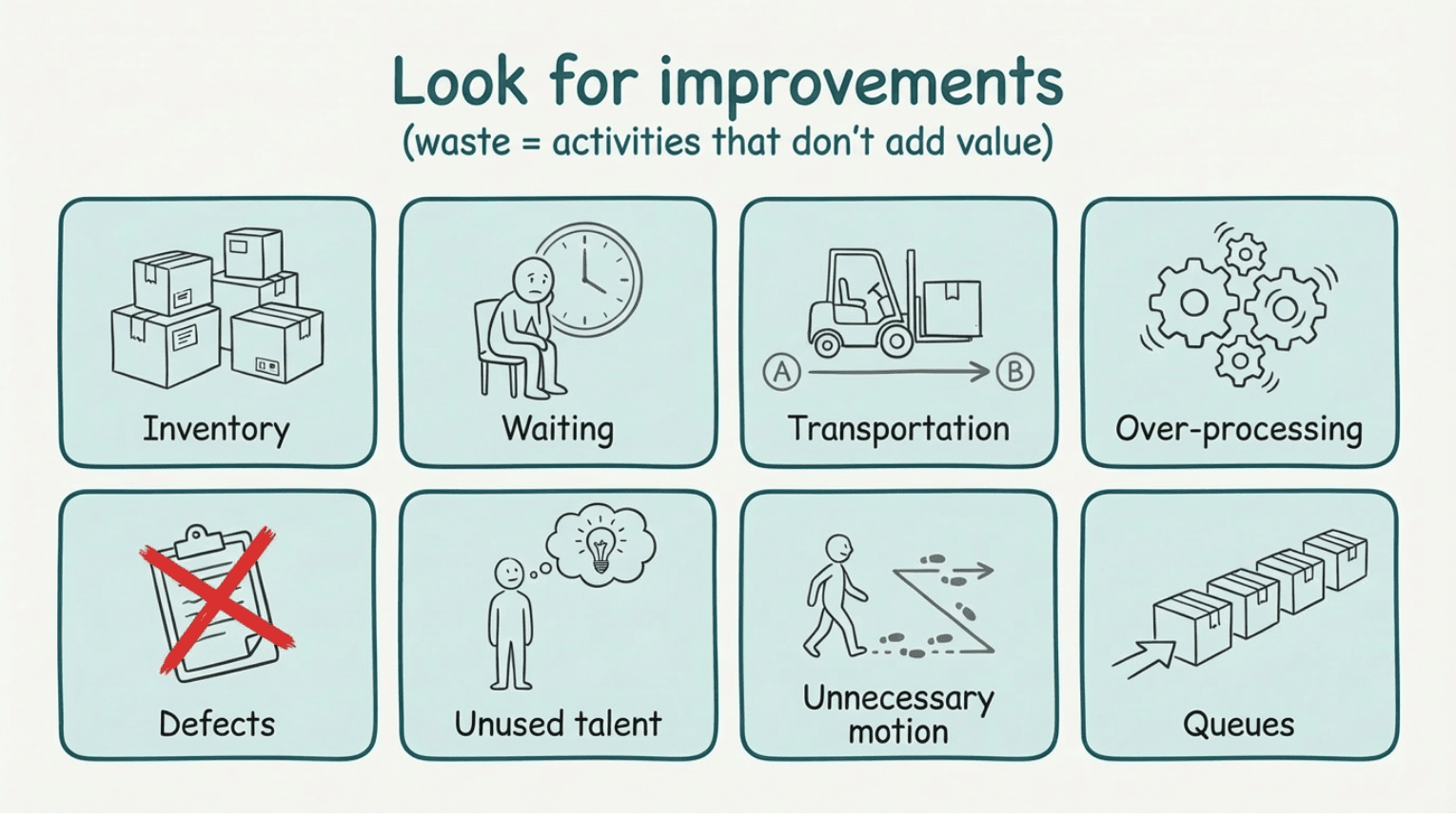

Once you've mapped the process, systematically look for activities that don't add value. This is called waste.

In process maps you see waste as:

• Loops back to earlier steps (defects, rework)

• Activities without clear value creation (over-processing)

Value stream mapping and spaghetti diagrams also show queues/inventory (overproduction), bottlenecks (waiting), transportation & motion.

How detailed should process maps be?

"Flow charts should be as simple as possible, but not simpler" - Albert Einstein

Think about purpose when considering detail level. If the goal is to improve a process that's too slow, you must include details that give understanding of why you're slow. Without these details, you won't progress. Include irrelevant details and you waste time.

Who should participate when we map?

Those who actually do the work. Leaders can contribute with overview, but the process must be mapped as it's actually performed - not as leadership thinks it works.

What do we do after mapping?

Systematically look for improvement opportunities (see image above). Ask improvement questions: Where are the bottlenecks? Where's the duplicate work? Where do things fall through the cracks? Prioritize improvements based on what gives the biggest effect.

Can we map ourselves, or do we need external help?

You can map yourselves after training. External help is useful the first time to learn the method correctly and avoid common mistakes. After that, you can do it internally.

The most important thing for getting good at process mapping is to practice. The hallmark of a good process map is that it delivers results - fewer misunderstandings, less waiting and queues.

How do we ensure process maps stay updated?

Make it part of improvement work. When the process changes, update the map. Use it in training new employees. If it's not used, it won't be updated.

Want your team to see the bottlenecks, duplicate work, and improvement opportunities?

Our Value Stream Mapping course teaches you how to map and improve processes with process maps.

Need help getting started? We facilitate process mappings and teach the team the method along the way.

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up