I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

«A bad process will beat a good person every time» W. Edwards Deming

How well do your process flow? Are your activities value-adding?

What do you measure to ensure good quality?

Does everyone agree on how the process is performed?

Is the process performed the same way every time?

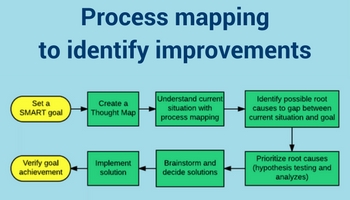

To improve a process, we need to understand it. Process mapping helps us understand our process to improve. They are an important and powerful tool for improving the effectiveness and efficiency of a process.

There are different process maps for different purposes. They all have in common that they are visual and make it easier for people to understand their role and how they fit into the big picture.

Process mapping focus on the process, not the people. If a process does not work properly, it does not help with skilled people to perform the process.

Here are some advantages with process maps:

Start by identifying the scope of you process: what is the start and end of your process?

Then identify all activities that are performed between start and stop, together with those who perform the process.

If you are in doubt about how the process is carried out, or want confirmation that you have the correct understanding: "Go to Gemba". "Go to Gemba" means going to where the process is performed.

Keyword for process mapping is "Actual": Go to the actual place, talk to the people who perform the process and map the actual process.

Ask questions and interview those involved in the process.

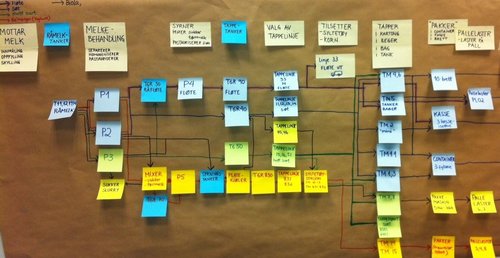

You can use brown paper and post-it notes in different colors, or you can use a blackboard.

Once the process is mapped, it is easier to identify improvements.

Questions lead to improvements. Challenge established truths and current practice. Continue to ask if you get answers like "We have always done it this way". Remember there are no stupid questions! Here are some examples of questions to ask to identify improvements:

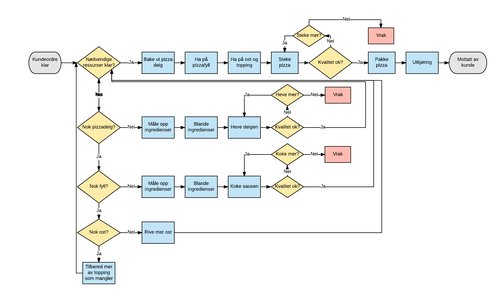

There are many types of process maps. Choose one that fits for your purpose. Here are some examples:

Which process map is the best for your process?

Lean Tech facilitates process mapping. Contact us if you are interested!

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up