I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

The Lead Lean conference focused on exploitation (optimization) and exploration (innovation).

How can Lean Six Sigma contribute to both?

The Lead Lean conference organized by Nordic Business Forum (22nd of January 2018) was an inspiring meeting with talented speakers like Anita Krohn Traaseth, Alex Osterwalder, Dan Toma, Eric Ries & Seth Godin.

A recurring theme during the day was exploitation and exploration.

Exploitation is associated with incremental innovations on existing processes, services and products to make the best use of resources. Exploration is about radical innovations such as the development of brand new processes, services and products.

Continuous improvement efforts focus on incremental innovations - improvements to existing processes, products or services.

Lean Six Sigma is a fact-based improvement method to achieve measurable results such as reduced costs, improved quality and increased capacity. It is a widespread improvement method for incremental innovations: optimizing existing processes, products and services.

Can Lean Six Sigma also contribute to radical innovations?

Let's start with Lean and Lean Startup.

Lean focuses on reducing waste, which the customer is not willing to pay for.

When developing brand new products or services, you have limited information about customer value. Because of this Eric Ries has chosen a new definition of waste in his book "The Lean Startup":

Waste are activities that do not contribute to validated learning

Validated learning can be documented with empirical data from real customers.

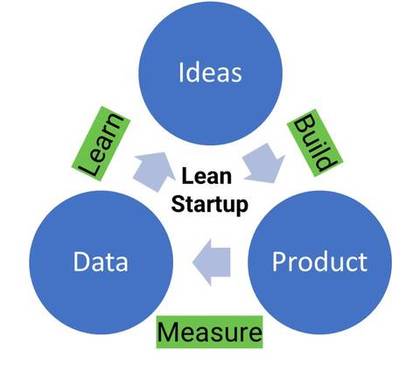

To reduce activities that do not provide validated learning, the Lean Startup model include the following steps: Build - Measure- Learn, see illustration.

We start with an idea we want to test. By building a prototype of the product, we can test how well our target customers likes the idea. The testing is done to retrieve data about customer response. Based on the data, we can learn what the customers likes and doesn’t like.

If they are not satisfied, we can develop the original idea and build a new prototype based on the lessons of the first prototype. This way we can continue to test prototypes, measure and learn until we have a solution we can scale up.

The target of this method is to develop product solutions as quickly as possible without spending too much resources. This is done by testing on a small scale and getting data on customer response early.

Can Six Sigma contribute to radical innovations?

Six Sigma use DMAIC (Define - Measure - Analyze - Improve - Control) to structure improvement work focusing on optimization and incremental innovations. The steps in DMAIC includes:

Define - Define projects based on business goals and strategy. Understanding the problem / challenge that needs to be solved and setting measurable goals.

Measure - Measure the current situation by obtaining relevant facts and data

Analyze - Analyze data and determine root causes of gap between desired situation and current situation

Improve - Get ideas of how to solve root causes, evaluate cost and effect of ideas, and implement chosen solution

Control - Sustain the gains

DMAIC is well suited for optimization of existing processes, products and services

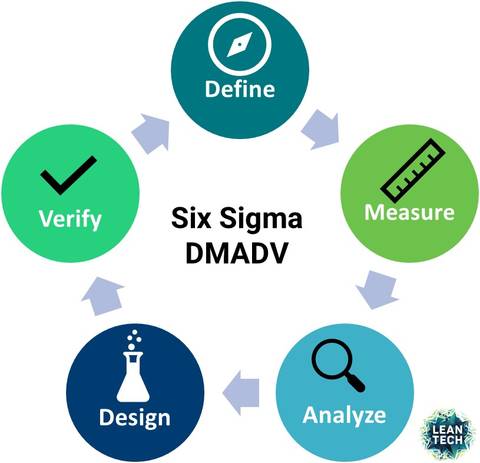

When developing new products, DMADV (Define - Measure - Analysis - Design - Verify) is used, where the Improve phase is replaced with Design and Control with Verify. See illustration

During the Design phase, a new process, product or service is designed, while Verify is about verifying that the product works as desired. These two phases are comparable to Eric Ries' Build - Measure - Learn.

Although the DMADV model in Six Sigma seems more comprehensive than the Lean Startup model, the goal is the same:

Create new products or services that provide customer value quickly, using minimal of resources

Design of experiments (DOE), Components of Variance (CoV) and multivariable analyzes are used in Six Sigma to develop good quality products, fast with minimal use of resources

Regardless of the improvement method or innovation model, efficient and effective testing methods (like DOE and CoV) will help you develop good solutions quickly and cost-efficient

If you prefer the Lean Startup model rather than Six Sigma's DMADV, experimental design can still help you develop prototypes and analyze customer response data.

Experimental design can test several variables at the same time and determine interactions (factors that affect each other). If one factor is tested at a time (OFAT), we will not learn about interaction effects and the trials will take longer.

Components of variance (CoV) helps you understand what factors contribute to variation, for example: What distinguish customers who like your product from those who do not like it?

"Design of Experiment (DOE), normally leads to products with better quality, using less time and resources."

Chronicle of John Tyssedal & Øystein Evandt in Tekniske Ukeblad no.0717

DOE can also be used in digital marketing. If your advertising hasn't reached your target audience, it's easy to draw the wrong conclusion when analyzing customer response. By including factors related to the audience in your tests, you can better understand your audience. Here is an example:

You have a new product you want to market, and want to test different ads to understand how to reach your target audience. You want to use Facebook for advertising and believe the following factors affect the response of the ad

1.Headline, 2. Image versus video, 3. Layout, 4. Background color

You create 2 ads with different headlines and keep the one with the best response. You create 2 new versions of the ad: one with picture and one with video. The one with the best response is tested with 2 different layouts. The layout with the best response is tested with 2 different background colors. The one with the best response is used in a major marketing campaign. You have completed 4 split tests, each test taking 1 week, a total of 4 weeks.

Experimental design allows you to include several factors and get results faster

Let's say you want to use experimental design and you are interested in how different audiences respond: Will the response to different lay-outs be affected by gender? Will the response to video versus image be affected by age? Will the response of different headlines be affected by which country you are from? By using a reduced experimental design, you can test the following 7 factors with 8 different ads (same number of ads as in the 4 split tests described previously):

1. Headline, 2. Image versus video, 3. Layout, 4. Background color, 5. Gender, 6. Age, 7. Country

The 8 different ads are tested for 1 week to determine the effect of the 7 factors. By analyzing Customer Response data, you can learn how to customize ads to different audiences and what characterizes the audience with the best response.

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up