Very engaged and focused throughout the course. Sticking to the agenda. Nice and pleasant.

You learn to improve your own processes using structured problem-solving:

Setting clear goals, obtaining data and facts to uncover causal relationships, introduce simple, and effective solutions that last.

The course combines 2 web meetings of 2 hours with 1 day classroom.

This training enables you to:

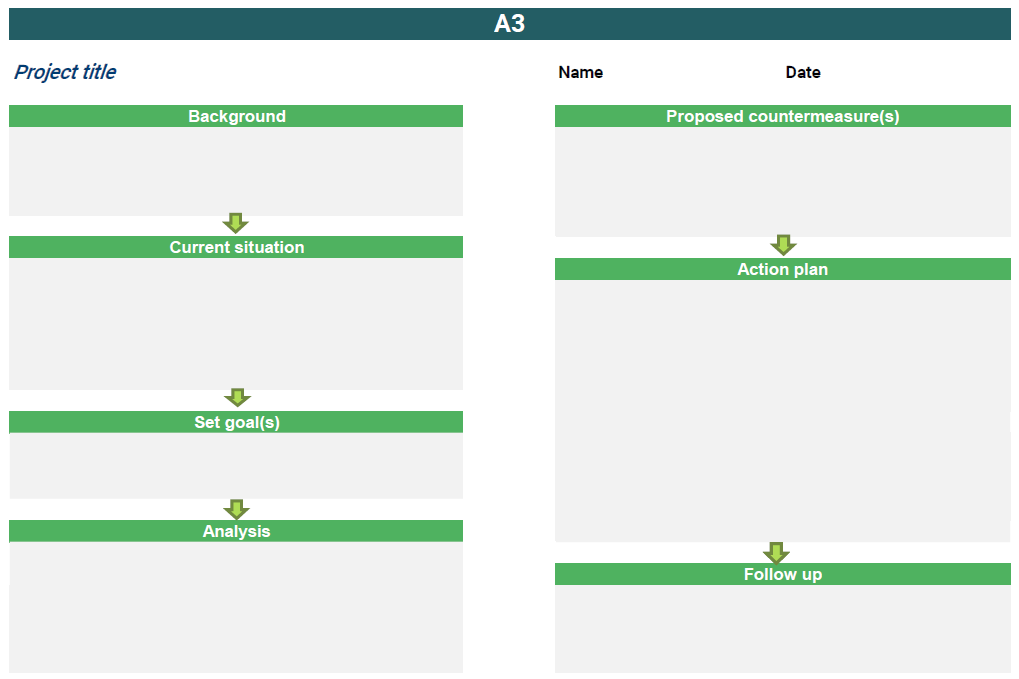

You learn to use an A3 template to solve problems / improve processes a systematic way, using 7 steps:

Start with Background, understand Current situation, set a Goal, Analyze and prove root causes, consider Measures and create an Implementation plan. Follow up to ensure lasting results.

The first web meeting teach you how to use an A3 for basic problem solving.You use the A3 template to solve a relevant problem and submit it for feedback. In the next web meeting, all participants receive feedback on their A3.

Between the 2 web meetings, there is a 1-day classroom course where we use a Lego game to practice structured problem solving and Lean solutions to reduce waste. The classroom training lets you practice A3, process mapping and lean principles to improve flow using a Lego game.

In the first webmeeting you learn to use an A3 template (see picture) to solve problems successfully:

Between the 2 online meetings, you solve a relevant problem using the A3 template.

In the last web meeting (~1 month after the first meeting), all participants receive feedback on their A3.

Choose a problem that is realistic to solve in 1 month. If your A3 is not completed, we can go through what you have.

We use Lean principles and solutions to improve a Lego manufacturing process.

The game was developed by John Bicheno at the Lean Enterprise Research Center and further developed by Joakim Hillberg at Revere in Sweden.

Companies, universities and consultants from several countries use this game to provide practical experience and understanding of Lean principles.

Courses can be arranged on request and customized to your business needs.

Your own data can be used in examples and exercises.

Open courses are arranged according to the Course Calendar.

You can start e-learning when you want. You have access for a year and unlimited attempts to successfully complete multiple-choice exam.

Lunch, refreshments, and drinks during classroom training are included, and you receive a course completion certificate.

Course location varies; check "Place" in Course Calendar.

Lean Tech is located at Kristoffer Robins vei 13 (0978 Oslo) and organizes courses here.

We have an agreement with Thon Hotels and organize courses in other locations as needed.

Sissel Pedersen Lundeby is IASSC (International association for Six Sigma certification) accredited trainer associate:

"This accreditation publically reflects that you have met the standards established by IASSC such that those who participate in a training program led by you can expect to receive an acceptable level of knowledge..."

Sissel has a Master in Chemical Engineering and more than 20 years' experience within manufacturing and environmental technology. She has practiced Lean Six Sigma since 2002, completing Black Belt projects and certification through Cytec (2004) and IASSC (2017).

She use Lean Six Sigma to create measurable results and want her course participants to be successful improving their processes. That's why her training focus on practical application.

"Inspiring, professionally competent, popularize a theoretical discipline"

Espen Fjeld, Commercial Director at Berendsen

"Academic highly skilled and clear performance. Fun and builds trust"

Jon Sørensen, Production Manager at Berendsen

"10/10 good at reaching everyone"

Erlend Stene, Sales leader at Berendsen

"Clear and well presented. Good at asking questions and listen (check understanding)"

Morten Bodding, Production Manager at Berendsen

"Made a difference, engaged and skilled"

- Participant from EWOS

"You are inspiring, positive and professionally skilled"

- Participant from EWOS

"Clear presentations and well explained"

"I thought it was very rich, with good examples that made me reflect"

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up